Vernier Clinometer and Micrometer Clinometer

🔗What is Clinometer? How to measure using Clinometer?

🔗Applications, Advantages and Disadvantages of clinometer

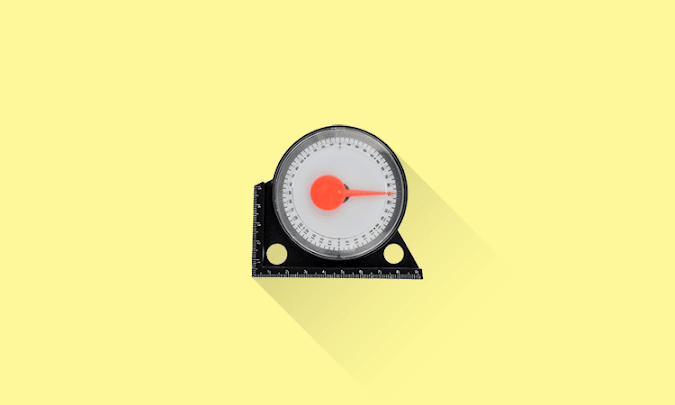

Vernier Clinometer

The Vernier clinometer is a vital precision alignment tool used across many industries. It consists of a spirit level mounted on a rotary member enclosed in a right-angle shaped housing. The housing has one face that forms the base of the clinometer. A circular measurement scale engraved in the housing is used to measure the angle of inclination of the rotary member relative to the base. The scale may cover a full circle or just a portion of a circle.

To use the clinometer, the base is placed on the surface to be measured. The rotary member is adjusted until the spirit level bubble is centered at zero. The rotation angle shown on the circular scale is then read against an index mark to determine the angle between two adjacent faces of an object or the inclination from horizontal or vertical.

Vernier clinometers are ideally suited for precision levelling and alignment tasks, such as:

Proper alignment is critical across many industries, especially those relying on precision machinery. Even very slight misalignments can cause significant issues in production. Businesses can accurately align their equipment and ensure optimal functionality by using a quality Vernier clinometer. Vernier clinometers are versatile, portable, and easy to use, making them an essential alignment tool.

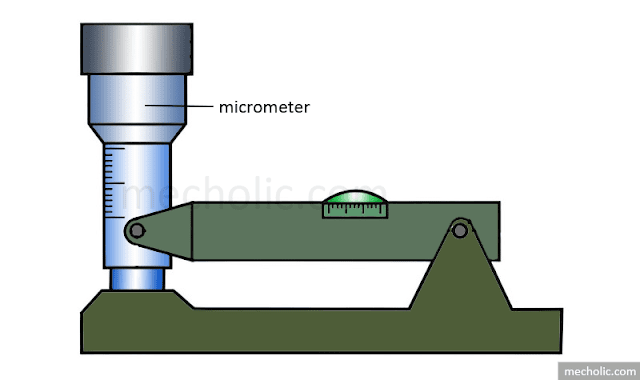

Micrometer Clinometer

The micrometer clinometer is a specialized type of clinometer used for accurately measuring small angles of inclination. It functions by incorporating a spirit level with a micrometer.

In the micrometer clinometer, one end of the spirit level attaches to the outer end of the micrometer barrel, while the other end is hinged to the base. The base is placed flush on the surface being measured. The micrometer is adjusted until the spirit level bubble is perfectly centred, indicating a horizontal or vertical zero reference point.

The micrometer spindle attaches to the base at a set distance L, usually 200 mm, from the hinge. With the base placed on the test surface, the micrometer is used to raise the spirit level until it is precisely horizontal. The reading shown on the micrometer dial is then divided by the set distance L to calculate the tangent of the angle.

The precision of a micrometer combined with the sensitivity of a spirit level allows the micrometer clinometer to measure very small angles of inclination to a high degree of accuracy. This makes it ideal for jobs requiring precision angle measurement, such as alignment of sensitive equipment or investigating settling in structures. The micrometer clinometer is an essential inspection and measurement tool across fields like machinery fabrication, construction, and metrology.