Pulsed MIG Welding - Types, Application, Advantages and Disadvantages

🔗Metal Inert Gas (MIG) welding process, Basic components and Process variables

🔗Applications, advantages and disadvantages of MIG welding

What Is Pulsed MIG Welding? How It Works?

Pulsed MIG welding is an innovative arc-welding process that offers significant advantages. One notable benefit is the precise control of droplet transfer, resulting in tiny and uniform droplets with minimal spatter. As a result, the weld bead exhibits a smooth and aesthetically pleasing appearance. This method has gained popularity due to its ability to operate with lower heat input, making it well-suited for welding thin workpieces and nonferrous materials.

Pulsed MIG welding is predominantly used for welding aluminium and stainless steel, although it can be used for ordinary carbon steel welding. Compared to short arc GMAW, this method operates at a slightly slower maximum speed of 85 mm/s or 200 in/min. Additionally, the process requires shielding gas, primarily argon, with a low concentration of carbon dioxide.

To implement the method, a dedicated power source capable of generating appropriate pulses (30-300 Hz) is necessary to regulate the droplet transfer. This capability extends the spray arc range down to low welding data, offering a stable and spatter-free arc. As a result, it serves as an appealing alternative to short arc welding.

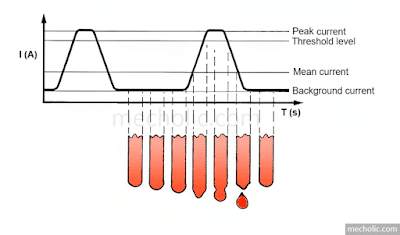

Pulse-spray welding is a modified version of the spray transfer mode that utilises a pulsing current. This current melt the filler wire, allowing a single small molten droplet to fall with each pulse. Using pulses reduces the average current, resulting in lower heat input. This decrease in heat input leads to smaller weld pools and heat-affected zones, enabling the welding of thin workpieces. The pulses from the power source synchronise with the wire feed speed, preventing short circuits and minimising spatter generation. This characteristic makes the process suitable for a wide range of metals, including the use of thicker electrode wire. The smaller weld pool enhances the versatility of pulse-spray welding, allowing welding in all positions.

Pulsed arc welding provides a stable and controlled droplet transfer, allowing for the utilisation of larger electrode diameters. This capability is particularly advantageous in aluminium welding, where the softness of the electrode poses feeding difficulties. However, the choice of shielding gases is limited in pulsed welding. Like spray arc welding, the argon/CO2 shielding gas mixture must not have a high concentration of carbon dioxide (CO2). The commonly used 80/20 mixed gas, typically employed in short arc welding, represents the maximum acceptable threshold.

Classification Of Pulsed MIG Welding

Pulsed arc welding offers diverse welding parameters, making it suitable for various plate thicknesses. However, achieving optimal results necessitates the careful coordination of multiple welding parameters, such as pulse-current duration (tp) and amplitude (Ip), background-current duration (tb) and amplitude (Ib), and wire-feed speed (Vf). Proper coordination of these parameters is vital to obtain a satisfactory arc. Nevertheless, external disturbances can still affect the arc, leading to arc stability disruptions and compromising the weldment quality.

The pulsed MIG process can be classified into the following categories

1. Pulsed MIG Using Synergic Control

It is initially developed by TWI in the UK, and has become a prevalent technique employed across industries worldwide. This control system incorporates a power source with two constant-current output characteristics. By periodically switching these characteristics, a pulsed current is generated. The switching frequency is synchronised with the wire-feed speed, which is determined using a mathematical model. This unique one-knob control mechanism enables the attainment of optimal and consistent droplet transfer throughout the welding process.

2. Pulsed MIG Controlled by Instantaneous Arc Voltage

It operates based on a fundamental principle illustrated in the following figure. The power source is equipped with two constant-current output characteristics. Two arc voltages, denoted as A and B in the figure, are set for effective control.

When the arc operates on the background-current characteristic, the wire-feed rate exceeds the melting rate, causing the arc to shorten and the operating point to move downward along the power source’s output characteristic. Once the arc operating point reaches point A, the control circuit activates the power device, transitioning the arc to the pulsed-current characteristic. During this phase, the wire-feed rate becomes lower than the wire-melting rate, resulting in an upward movement of the arc operating point along the pulsed-current output characteristic. Once it reaches point B, the control circuit triggers the power device, returning the arc to the background output characteristic. This process repeats continuously, causing the arc length to vary between La1 and La2. A stable arc can be achieved by selecting appropriate points A and B.

To ensure successful droplet transfer during each pulse, the control circuit must be modified to avoid excessively short pulse durations preventing droplet transfer. This control system exhibits remarkable self-regulation of the arc length, maintaining arc length even when there is torch or wire feed shakes.

3. Pulsed MIG Controlled by An Arc-Length Feedback Circuit

Extensive research projects on arc-length feedback control have been conducted domestically and internationally. Based in Japan, Mitsubishi Company has made notable progress in this field. Their system simultaneously utilises open loop and feedback loop mechanisms to regulate pulsed MIG welding. Based on a mathematical model, a wire-feed rate signal is employed to control the pulse frequency, ensuring the melting rate matches the wire-feed rate. An average arc-voltage signal is also utilised in the feedback loop to adjust pulse parameters and compensate for random disturbances. However, this system has a drawback: the time required to calculate the average arc-voltage signal adversely affects the control’s dynamic characteristics. Moreover, the average arc voltage fails to accurately represent the arc length in the presence of arc blow. Another proposed feedback control method addresses this issue by considering the arc voltage at a specific instant during each pulse period (e.g., the arc voltage 1ms after the leading edge of the pulse current) as the arc length, which is then utilised as the feedback signal in the circuit. Typically, the feedback loop governs the duration of the background current, thus enabling control over the pulsed MIG process.

Applications Of Pulsed MIG Welding

Pulsed MIG welding primarily applies to aluminium and stainless steel welding. It's renowned for its exceptional stability at lower current levels, making it a preferred alternative to the colder short-arc welding method, especially when working with aluminium.

Advantages and Disadvantages of Pulsed MIG Welding

Advantages Of Pulsed MIG Welding

1. Pulsed MIG welding offers excellent weld quality and appearance. The process gives cleaner, spatter-free welding, surpassing traditional welding methods in aesthetics.

2. Heat control: One of the critical advantages of pulsed MIG welding is its ability to control heat input effectively. By initiating a background cycle, the welding process prevents excessive heat from affecting the welded pieces. This is particularly beneficial for delicate and thin materials, as it minimises distortion and burn-through. Pulsed MIG welding is commonly used for aluminium welding but can also be advantageous for stainless steel, nickel, and other heat-sensitive alloys.

3. Pulsed MIG welding provides the ability to extend spray arc welding to lower welding data, making it well-suited for welding materials like stainless steel and aluminium. This capability enables the welding of thin materials and facilitates positional welding, delivering superior results compared to short-arc welding techniques.

4. In some instances, pulsed MIG welding is employed within the normal spray arc range to achieve better penetration into the material.

5. Another advantage of pulsed MIG welding is the ability to use slightly thicker filler wire, which is cost-effective and easier to feed. This advantage is particularly valuable when welding aluminium since thin aluminium wires are challenging to feed due to their softness.

6. Research has demonstrated that efficient droplet pinch-off during pulsed MIG welding reduces the overheating of droplets, leading to reduced fume production.

Disadvantages Of Pulsed MIG Welding

1. Cost: Pulsed welding equipment tends to be more expensive than traditional welding equipment, which can pose a challenge for smaller welding operations or those with limited budgets.

2. Complexity: Pulsed welding techniques require more skill and training than traditional methods. Mastering the various parameters and settings that control the welding process takes time and practice. To simplify the learning curve, we recommend pulsed welders equipped with synergic control, which offer a user-friendly interface suitable for beginners.

3. Production speed: Generally, pulsed welding exhibits slower production speed than short arc welding. Compared to short arc welding, the higher heat input associated with pulsed welding reduces the maximum usable wire feed speed.

4. Shielding gas limitations: Pulsed arc welding restricts the choice of shielding gases. Similar to spray arc welding, the carbon dioxide (CO2) concentration in an argon/CO2 mixture must not exceed certain levels.

.png)

.png)