Metal Inert Gas Welding Process, Basic Components and Process Variables

What Is MIG WELDING

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a popular process that utilizes a consumable wire electrode and a shielding gas to create solid and durable welds. Advancing developments in metallurgical engineering enabled the replacement of traditional flux coatings with inert shielding gases to prevent contamination weld. Key advantages of the MIG process include enhanced productivity through higher welding speeds, versatility in numerous joint configurations and materials, and relative simplicity of operation compared to other arc welding methods.

🔗Tungsten Inert Gas (TIG) Welding Process

🔗What are the difference between MIG welding and TIG welding

🔗Electroslag welding process - Application advantages and disadvantages

Basic Components and Working of MIG Welding

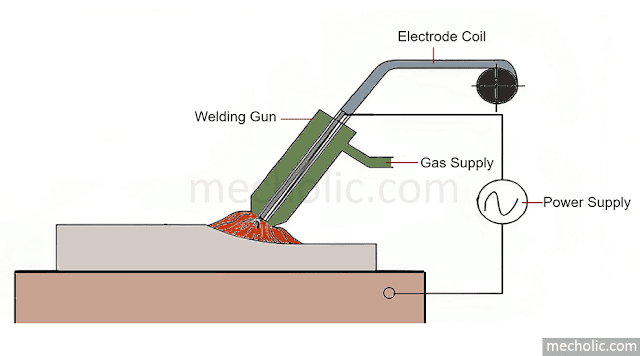

The fundamental equipment required to undertake MIG welding includes a welding torch, wire feed mechanism, power source, consumable wire electrode, shielding gas supply, and control unit. MIG can be conducted in either semi-automatic or fully automatic, depending on the integration of automation components.

Welding Gun and Wire Feed

The welding gun, resembling a pistol in appearance, is a pivotal component in the MIG welding process. Welding gun featuring a trigger mechanism to initiate various integrated operations, including wire feed, shielding gas flow, electric power supply, and arc striking. It is designed with a nozzle through which the shielding gases are expelled. Depending on the power rating, the nozzle may be air-cooled, suitable for low-power guns operating at approximately 200 A, or water-cooled, applicable for high-power ratings. The nozzle is typically constructed from durable refractory ceramic composites to withstand high temperatures at the arc zone. The welding wire, sourced from a spool, is drawn and guided through drive rolls within the welding gun. The wire feed rate is carefully regulated to maintain a steady arc voltage throughout welding.

Electrode

The electrode is represented by a metallic alloy wire called MIG wire. The selection of the electrode, including its alloy composition and size, is primarily driven by several factors, including the base metal composition, the specific process variation employed, joint design considerations, and the condition of the material surface. The choice of electrode significantly influences the mechanical properties exhibited by the resulting weld, thereby playing a crucial role in determining the overall weld quality. It is worth noting that commercially available electrodes incorporate small amounts of deoxidizing metals, such as silicon, manganese, titanium, and aluminium, to effectively counteract oxygen porosity formation. Some electrodes may also contain denitriding metals, such as titanium and zirconium, to mitigate the occurrence of porosity caused by nitrogen.

In the MIG welding process, continuous and controlled electrode melting occurs as it is continuously added to the weld. A suitable motorized mechanism propels forward the uncoated consumable electrode. The electric arc causes the wire electrode to undergo melting, thereby functioning as a filler material to facilitate the formation of a weld joint. The diameter of the electrode commonly ranges from 0.70 to 2.40 mm, although larger diameters of up to 4.00 mm may also be used. In most instances, the wire feed rate ensures a constant supply of the electrode, which can be as high as 30 m/min. However, the rate may vary between 2 to 10 m/min for semi-automatic processes.

Gas Supply System and Necessary Valves

The primary function of the inert gas employed in welding is to safeguard the weld from potential airborne contaminants. To achieve this, gases such as argon, carbon dioxide, and helium are commonly used due to their superior shielding capabilities. Among these options, argon is frequently favoured in welding due to its wider availability compared to helium. Additionally, argon consumption is typically lower as it possesses a higher density than helium. A mixture of argon and helium is the most suitable choice for welding soft metals like aluminium. However, it is essential to note that different proportions of the gas mixture can be used for welding both ferrous and non-ferrous metals. The specific mixing proportions, however, should be selected in accordance with the manufacturer’s instructions and recommendations.

Due to the associated cost, MIG welding is limited to welding steels in the early stages. However, several years later, the introduction of semi-inert gases, specifically carbon dioxide, revolutionized the landscape. This breakthrough led to the increased adoption of MIG welding. Presently, GMAW stands as the most prevalent welding technique in industrial settings, owing to its remarkable versatility, high-speed capabilities, and the relative ease with which it can be integrated into robotic automation systems.

Power Source

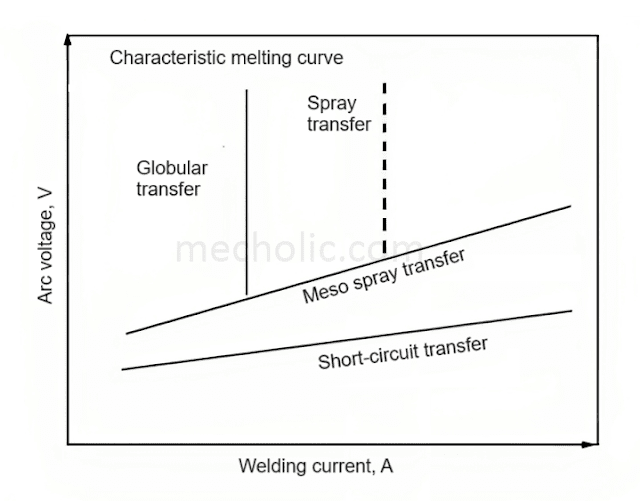

Direct Current Reverse Polarity (DCRP) is generally favoured in welding to take advantage of the self-regulating arc characteristics. However, a Constant Arc Voltage (CAV) system is employed when dealing with large diameter electrodes, which incorporates a variable speed electrode and feed drive system to maintain proper arc length. An Alternating Current (AC) supply is avoided due to the unpredictable behaviour of the arc. Different modes of transfer, such as short-circuiting, globular, and spray transfer, are influenced by the increase in welding current, especially in welding aluminium alloys.

Control Unit

The control unit is the central component responsible for coordinating various functions within the gas metal arc welding (GMAW) process. It effectively manages the power supply, wire drive, and gun movement and regulates gas and water supply (if necessary). Inadequate gas flow rate or insufficient water supply can result in the unit shutting down.

In GMAW, there are four primary methods of metal transfer: globular, short-circuiting, spray, and pulsed spray. Each method possesses distinct properties, along with corresponding advantages and limitations. The influence of welding current on metal transfer modes in GMAW, particularly for aluminium alloys, is graphically depicted in the Following Figure.

🔗Applications, Advantages and Disadvantages of MIG Welding

Role of Gas in MIG Welding

In the earlier days of stick welding, bare metal electrodes were employed but yielded limited success. These electrodes did not provide adequate protection for the weld, leaving them susceptible to the surrounding air. Consequently, the welds would absorb oxygen, nitrogen, and water vapour, resulting in weakened and brittle joints, particularly when working with steel.

However, the introduction of MIG (Metal Inert Gas) welding revolutionized the welding process. In MIG welding, a shielding gas is utilized to safeguard the weld from the surrounding atmosphere. This shielding gas acts as a protective barrier, preventing the absorption of harmful gases and moisture during the welding process. Additionally, MIG welding utilizes a bare metal electrode wire that is continuously fed, creating continuous welds.

Gas in MIG welding serves two essential purposes: shielding and stabilizing the arc. The choice of shielding gas plays a crucial role in the success of MIG welding, as it helps protect the weld pool from atmospheric contaminants and influences the characteristics of the weld. It stabilizes the electric arc, allowing for consistent heat transfer and improved control over the welding process.

MIG Welding Process Variables

The MIG welding process is influenced by several crucial variables that are listed below:

1. Electrode size, inclination, and extension. Extension is the distance between the contact tip and the end of the electrode.

2. Welding position: The welding position, such as flat, horizontal, vertical, or overhead.

3. Welding travel speed: The speed at which the welding torch moves along the joint, known as welding travel speed.

4. Welding current and arc voltage

The most influential variables in the MIG process are welding current, voltage, and travel speed. These variables primarily affect penetration depth, deposition rate, bead size, and weld metal quality. Arc voltage has a greater impact on the width of the weld bead. Higher welding speeds generally result in lower weld penetration. Excessive heating caused by a high welding current can lead to weld sagging in the workpiece. However, for larger diameter electrodes, using higher current levels with a shorter electrode extension can be beneficial for achieving better weld bead geometry.