Types Of Crankshaft Position Sensors How They Work?

🔗Crankshaft Position Sensor: What Is It, Why Is It Important?

Various kinds of crankshaft position sensors are available, each with its own set of characteristics. These include inductive sensors, Hall Effect sensors, magnetoresistive sensors, and optical sensors. Among these, inductive sensors are the simplest in construction, which are usually passive devices.

Two common types of magnetic sensors are magnetoresistive sensors that generate A/C voltage and a Hall-effect sensor that produces a digital square wave. Both types of sensors are reliable and accurate, but the hall effect sensor is more commonly used in modern engines. Hall effect and magnetoresistive sensors have an advantage over inductive sensors since they are capable of sensing static magnetic fields. Inductive sensors have a limitation in that they cannot detect static magnetic fields.

The Hall Effect crankshaft position sensor utilises a chopper disc that rotates inside the distributor. Whenever a metal vane comes between a magnet and a Hall sensor, the Hall sensor switches off. By analysing the pulsing speed, the computer can determine the engine RPM and the position of the crank during its rotation.

An optical crankshaft position sensor operates by shining light through slots in a circular plate. The plate that is attached to the end of the camshaft. As the plate rotates past an LED that provides the light, a sensor on the other side of the plate detects when it sees the light shining through one of the slots. Then ECU counts the light pulses. Some optical sensors have 360 slots in the plate, providing an incredibly fine engine speed resolution. The ECU can calculate the crank position by placing slots of different shapes in another location on the plate. While optical sensors can provide the most precise detection, they are not very resistant to fouling or contamination.

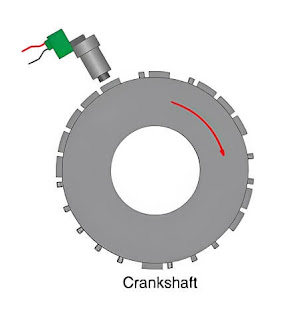

Certain engines, such as GM's Premium V family, use a reluctor ring that is part of the harmonic balancer to read the crankshaft's position. This method is far more precise than other techniques and enables the computer to determine the crankshaft's exact position within a few degrees at any given moment.

Currently, it is becoming more common to measure the crankshaft position directly rather than indirectly via camshaft position. To ensure measurement accuracy and avoid mechanical wear, it is essential to take these measurements without any mechanical contact with the rotating shaft. Non-contact measurement techniques that rely on magnetic or optical phenomena are widely used in automotive electronics for this purpose. Non-contact measurements of crankshaft position in engine are often accomplished using magnetic techniques, which are preferred because they are unaffected by contaminants such as oil and dirt.