Crankshaft Position Sensor: What Is It, Why Is It Important?

The effective functioning of automotive control systems relies not only on pressure sensing but also on the precise measurement of the position of shafts, valves, and levers. In automotive electronics, measuring the angular position or velocity of shafts is common. The crankshaft position sensor (CPS) is essential to modern engines. It plays a crucial role in providing vital information to the engine control module (ECM), which controls ignition timing, fuel injection sequencing and is responsible for regulating various engine functions. In this article, we will discuss a crankshaft position sensor, its importance, its functions, and its advantages.

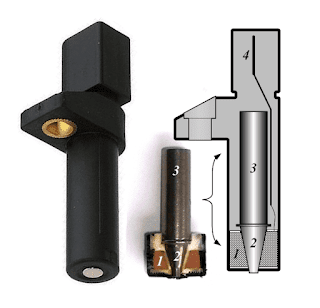

What Is a Crankshaft Position Sensor?

The angular position of the crankshaft is an important parameter in automotive control systems, especially for controlling the ignition and fuel injection timing. A crankshaft position sensor is an electronic device that detects the position and rotational speed of the crankshaft in an internal combustion engine. Depending on the engine type, the CPS can be found mounted on the main crank pulley, flywheel, camshaft, or crankshaft itself. Moreover, the engine speed indicator also utilises data from this sensor.

The engine control unit (ECU) relies on precise data regarding the engine's speed and the crankshaft's position in its rotation to enable accurate control of the engine's behaviour. This data is essential for the ECU to accurately time the firing of the spark and injection accurately, ensuring optimal performance. Furthermore, individual cylinder ignition and injection control also rely on this sensor data.

Before the development of electronic crank sensors, timing adjustment on petrol engines was accomplished by manually adjusting the distributor. This labour-intensive and time-consuming process required skilled mechanics to ensure accurate timing. The availability of electronic crank sensors has simplified this process and made it more accurate.

🔗What is Camshaft Position Sensor? Function and Purpose of CPS

🔗Types Of Crankshaft Position Sensors How They Work?

Functions Of Crankshaft Position Sensor

The crankshaft position sensor is responsible for providing accurate and timely information about the position and speed of the crankshaft. This information is crucial for the engine control unit to control engine ignition timing accurately and in which cylinder. Diesel engines rely on this sensor to regulate fuel injection. In addition, the sensor output can be used in conjunction with other data, such as cam position, to determine the current combustion cycle. This information is important for starting a four-stroke engine.

The CPS also helps the ECU to monitor the engine's speed and detect misfires.

Why Is a Crankshaft Position Sensor Important?

The crankshaft position sensor is important for several reasons. Firstly, it helps to ensure that the engine runs smoothly and efficiently. By providing accurate information about the position and speed of the crankshaft, the ECU can adjust various engine functions to optimise performance. Secondly, the crankshaft position sensor is essential for diagnosing engine problems.

🔗Can You Drive with A Bad Crankshaft Position Sensor?

A faulty crankshaft sensor can lead to rough starting conditions and even cause your engine to stop working altogether. If the sensor fails or becomes faulty, it can cause various engine issues, such as stalling, rough idling, and poor fuel economy. By detecting these issues early, mechanics can quickly diagnose and repair the problem before it causes further damage.

🔗How The Crankshaft Position Sensor Is Tested?

Benefits Of Crankshaft Position Sensor

The advantages of a crankshaft sensor in an engine are accurate ignition timing, thereby enhancing performance. By ensuring that the engine is timed accurately, improved fuel efficiency and reduced emissions are achieved. By providing accurate information about the position of the crankshaft, the crankshaft sensor can help identify potential issues early, allowing for prompt and cost-effective repairs.