Types of Autocollimators and Advantages of Visual, Digital, and Laser Autocollimators

🔗Autocollimator - Applications advantages and limitations

🔗Working principle of autocollimator

Several types of autocollimators are designed for specific applications and measurement requirements. Autocollimators mainly classified into

Visual autocollimator or conventional autocollimator

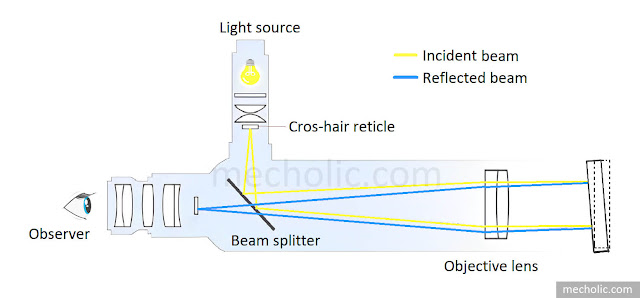

In this type of autocollimator, you can visually determine the displacement of the reflected image. A pinhole light source illuminates the autocollimator reticle in the focal plane of an objective lens. The light passes through the objective and is reflected back into the autocollimator by the mirror. Mirrors with a flatness tolerance of 1 μm per 100 mm are utilized to ensure high-quality results. A beam splitter is used to separate the outgoing and reflected light. The reflected image of the autocollimator reticle is projected on the eyepiece reticle, which is located in the objective lens' focal plane. The Visual autocollimator has the capability to measure angles as small as 0.5 arcseconds. Visual autocollimators are typically focused at infinity, thus allowing them to make short- and long-distance measurements.

Applications of visual autocollimator

- Measurement of angles up to 3”

- Verifying the accuracy of right-angle prisms for angular errors.

- Determining the flatness of machine tables, surface plates, and more.

- Checking the straightness of machine guide ways.

- Evaluating the parallelism of slide movements in relation to guide ways.

- Comparing angles of reflective surfaces.

Limitations of visual autocollimator

- Large in size.

- Low speed measurement

- Not suitable for dynamic measurement.

- Conventional autocollimators cannot detect the roll error motion.

Digital autocollimator

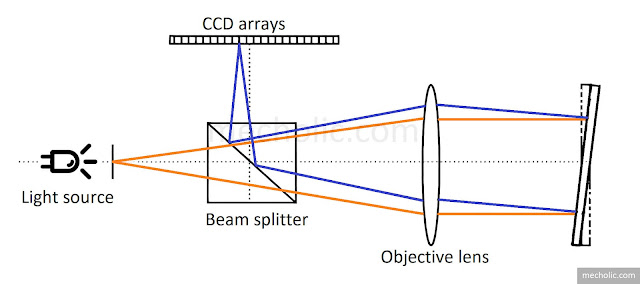

In digital autocollimators, the light source is focused the same way as in conventional autocollimators. The difference is in how the reflected light beam is detected. The electronic photo detector is used in digital autocollimator to detect the reflected light beam. The advantage of this is that it uses digital signal processing technology to detect and process the reflected beam. The deflected beam is then projected on a linear CCD array (Charge Coupled Device) located in the focal plane of the objective. Bi-directional autocollimators have separate measuring systems for both the X and Y directions. The measured distances are then converted into angle deviation. The electronic autocollimator provides high accuracy in angle measurements. Instruments in this category can measure up to 0.01 arcseconds of resolution and have a linearity of 0.1%.

Advantages of digital autocollimator

- High precision.

- As the output is digital, it can be easily transferred to a data acquisition system for storage and additional data processing.

- Measuring angles of both static and dynamic systems.

- Real-Time measurements

- Overseeing the alignment of large mechanical systems remotely.

- Automated alignment systems and monitoring of the movement of robotic axes

- Checking for angular errors in rotary tables, indexing heads, and machine part platforms

Laser autocollimator

This type uses a laser light source instead of a traditional light source. The power of the laser makes it difficult to determine the displacement visually. As a result, a different approach is implemented to record the instrument's measurements. The components of a laser collimator are all encased in a precisely machined barrel. A continuous wave plasma tube is used to generate a laser beam. The holding and supporting fixture are used to precisely centre the laser beam in such a way that the optical axis is exactly in line with the mechanical axis of the barrel. In conjunction with the spatial filter, the rear lens ensures a sharp laser beam. The sharp laser beam is then aimed at to target.

The instrument barrel, which houses the laser emitter, also contains a beam splitter and a set of photoelectric sensors. These sensors are arranged to only detect the return beam from the mirror and not the laser emissions. Unlike a visual autocollimator, the internal target in a laser collimator is a bi-cell array of sensors (BPD - bi-cell photodiode). There are two sensors to measure displacement on each axis. The sensor output is then translated into angular displacements by a logic circuit.

Advantages of laser autocollimator

- The laser autocollimator makes it possible to three axis measurements using a diffraction grating as the target reflector.

- The use of a laser source means that the sensitivity of angle detection is no longer dependent on the objective lens' focal length, resulting in a compact sensor size.

- The high intensity of the laser beam results in ultra-low noise measurements, thereby enhancing the measurement accuracy.

- The high intensity of the laser beam makes it suitable for measuring angles of very small objects (such as 1 mm in diameter) and for long measuring ranges that can reach up to 15 m or more.

- Another significant advantage is that a laser autocollimator can be used to measure surfaces that do not have mirror-like qualities.

- High-speed measurement.