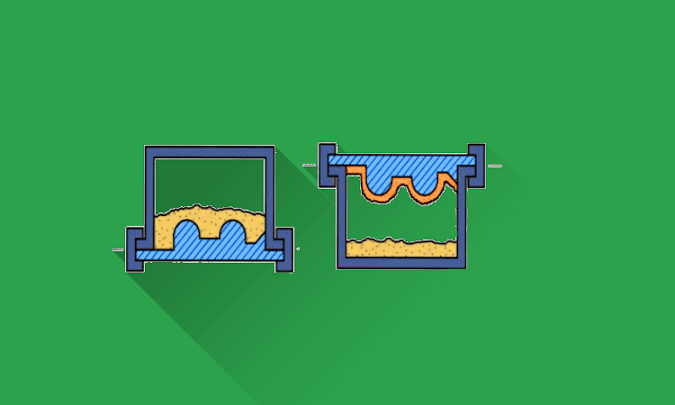

🔗How shell moulding is done?

Application of shell moulding

- Shell moulding is suitable for mass production of thin-walled casting in any metal having the size of 20kg. Most commonly used includes iron, bronze and aluminium alloy casting.

- The shell moulding is economical when a large number of thin-walled shell items with reasonable sharp corners and projection.

- The casting of small mechanical parts that requires high level of precision. E.g., Cylinder head, connecting road, gear housing.

- Production of high precision moulding cores. E.g., Engine block water jackets.

- Other applications include refrigerator valve late, cast tooth bevel gears, automobile transmission parts, chain seat brackets etc.

Advantages of shell moulding

- The process of shell moulding can be automated entirely for mass production

- Short lead time possible

- High productivity and low labour cost

- Low tooling and equipment cost.

- Many materials option

- Very little scrap is generated. The sand can be recycled.

- Excellent collapsibility as resin binder burns out in heat generated by molten metal, which makes shaking out of product is easy. So it requires a lower draft angle, which saves the material and subsequent machining costs.

- High permeability, varying wall thickness to be made without any venting difficulties. So, there is no need for a complex system of risers.

- Shell casting is more dimensionally accurate than sand moulding. Fewer restrictions in casting design.

- Complex shapes of fine details can be produced with excellent tolerance and a smooth surface finish. Smoother surface achieved by finer grain size.

- Thin wall of the shell rapidly heats up as molten metal is poured in it, preventing the chilling of metal as it is poured. It helps to the rapid flow of metal through runners allowing the filling of complex moulds and preventing possibility of a cold shut.

- Excellent tolerance and dimensional stability. Dimensional tolerance is as close as +.075mm. It helps to reduce machining costs.

- Excellent surface finish is obtained, and the surface is free from fins and blemishes associated with the green sand moulding.

- Since the sand has good strength, the mould can be designed to have an internal cavity directly with shell mould, thus eliminating the need for a mould core.

- The shell mould can be stored indefinitely for future use.

Disadvantages of shell moulding

- The pattern is expensive. Since the entire mould is formed from pattern, the pattern must include a gating system. It is economical only in mass production.

- High labour cost if it is done manually.

- High initial cost for specialized equipment.

- Dimensional limitation, a minimum thickness of cast is 4mm.

- Resin binders are expensive.

- Permeability of mould may decrease due to fine grains; there may be a chance of gas inclusion.

- Shrinkage can be a problem.