Factors Which Governs the Machine Design (General Considerations)

🔗Types of Machine Design - Adaptive design, Development design and New design

🔗General procedure in machine design

What are the factors to be considered in designing of machine parts?

General considerations in machine designing of machining component areTypes of load and stresses by the load: The load and stress on a component setup internal stresses. The type of load and stress acting on the machine component affect the designing of the component. Also, consider the suddenly applying loads (impact) on the machine parts.

High output and efficiency: Earlier machines are heavy and large power consuming. Now the trend is to use a full functional machine which gives high output and low power consumption. Now computer-controlled machines like CNC and DNC can produce components very fast and efficiently.

Kinematics of machine: The machine is designed in such a way that it gives the required output or motion with the simplest arrangement of parts. The types of motion in the component may be rectilinear (unidirectional and reciprocating movement), Curvilinear (rotary, Oscillatory, simple harmonic motion), constant velocity, constant or variable acceleration.

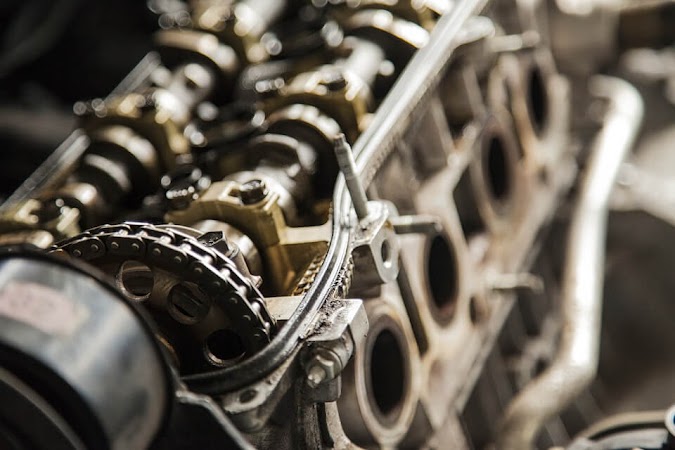

Selection of materials: Machine designer should be very well knowledgeable about the properties of manufacturing material he deals with. It includes the material of product on which machine is going to be used (in case of cutting tools). The machine should be strong enough to withstand the forces it is designed for. It should not undergo permanent plastic deformation during its lifetime. Some important characteristics of the material are strength, stiffness, wear resistant, machinability, resistance to heat, electrical conductivity, corrosion resistant, ductility, durability, malleability etc.

Lubrication and frictional resistant: Friction is the one of the main reason for power loss. The friction at staring of machinery is higher than that at running. The designer should give attention to the lubricating of surfaces which moves in contact. Application of lubrication between two mating surface reduce the friction and helps reduce the wearing of component.

Lightweight and minimum dimension: The machine should be rigid, strong, reasonably safe with lightest and smallest practicable cross-sections. This can be achieved by using hardening of metals and by using light weigh rolled sections.

Use of standard part and Interchangeability: Designer should be considered to use standard parts whenever it is possible. The components such as gears, screws, nuts, pins, pulleys, bearings etc. are included in this. Following the standard parts and interchangeability makes faster easier availability of components if it needs to be replaced. It will also reduce the cost of the machine.

Numbers of machine to be manufactured: The overhead expenses like engineering and shop cost should be considered if number of machines to be produced is low. If number articles is to be manufactured is low, then the high fixed charge on the article is not justifiable unless machine needs very special design. In small number of product, the designer should use standard parts as much as possible.

Workshop facilities and limitation: Designer should aware of the facilities and limitation of the workshop where the component is manufactured. Design and choose component accordingly to avoid the necessity of work done in some other workshop or necessity of installing new manufacturing machines. Consider using the latest technology available in the workshop.

Assembling and disassembling: All machines are manufactured in components and it must be assembled as a working unit before it undergoes testing. The large unit of machine is then transported to the place of service as a component. Then it is assembled at the final location. The designer should consider and easiness of transportation and assembling. Easiness of dissembling and assembling is important also in maintenance and repair of machine.

Convenient of handling and maintenance: The machine controller should be placed where it is convenient to access by the operator. The removal and replacement of workpiece as well as cutting tool etc. must be easy.

Safety of operation: The moving parts like belt drives, gears, etc of a machine cause workshop accidents. So the designer should always provide a means of safety to the operator which does not interfere with the operation of machine. The design should confirm the safety codes.

Cost of construction: In this age of competition, the cost is very important. So one of the aims of the designer should be to provide a high-quality product with minimum possible manufacturing cost.