Caulking and Fullering of Rivet Joint with Sketch? Difference between Caulking and Fullering

🔗What is Riveting metal joining process?

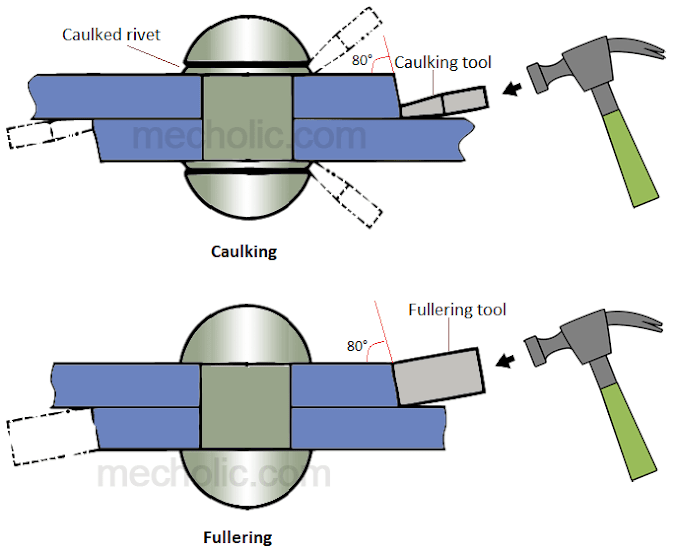

What is Caulking and fullering

Caulking is a process employed on riveted joints of pressure vessels like tanks, steam boiler to make joint leak proof and fluid tight. The narrow blunt chisel tool used for caulking is known as caulking tool. Caulking tool about 5mm thick, 38mm breadth and edge of tool is ground to an angle of 80°. The tip of the tool is forcing down (burring down) the edges of joint as well as the edge of rivet head as shown in figure. It closes all the asperities in the contacting surfaces. Caulking is done at the edges of plates in lap joint and edges of strap plate in a butt joint. The edges of plates are first bevel at 70-80° then caulking tool is hammered either by hand, hydraulic tool, or pneumatic tool. The blow on the caulking tool is closes to the plate, so a great care would be taken during caulking to avoided injury of main plates below the tool and that may open the joint instead of sealing it.Fullering is also a process to make a sealed joint. It is similar to the calking except the shape of tool. The tools used for this purpose is known as fullering tool. The thickness of fullering tool is equal to the thickness of plates. So the blow on the fullering tool results in simultaneous pressure on the entire edges of the plate. The fullering is more satisfactory than caulking because it gives a clean finish and less risk of damaging of plates.

Comparison between caulking and fullering

Caulking- An operation to make leak-proof joint; the outer edges of the rivet joint is hammered into seam.

- The narrow blunt tool used for caulking known as caulking tool.

- Caulking carried out at the edges of both plates and rivet.

- The thickness of caulking tool is about 5mm

- The risk of getting main plate damaged is high.

- The achieved is surface finish is not good as fullering.

Fullering

- A process to make leak-proof joint

- The tool used known as fullering tool

- Fullering is carried out only at edges of plates.

- The thickness of fullering tool is same as the thickness of plate.

- The chance to get main plate damaged is low.

- Very good surface finish.