Essential Parts of Modern Carburetor and Their Functions

🔗Design and working principle of simple carburetor

🔗Advantages and disadvantages of simple carburetor

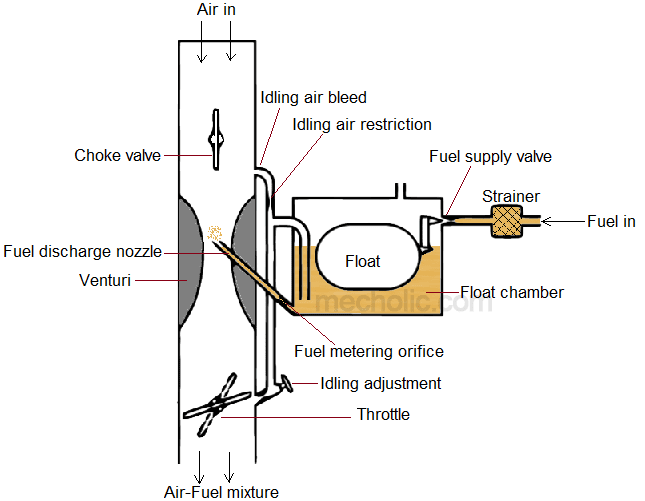

The modern carburetor has many essential parts. According to the functions they can be grouped into the

- Fuel strainer/ Filtering device

- Float chamber/ Float mechanism

- Main fuel metering and idling nozzle

- Choke and throttle

The functions of these parts in the carburetor is discussed below

Fuel strainer

Fuel discharge nozzle of a carburetor is very thin. It may get clogged during prolonged operation of the engine. To avoid the fouling, clogging of narrow discharge nozzle by the dust particle, the fuel is filtered using fuel strainer. In most carburetor fuel first enter into strainer chamber. Fuel strainer consists of a filtering method (usually fine wire mesh) and it will intercept dirt particles in the fuel. Fuel strainer is installed at the inlet of fuel chamber and may be cone-shaped or cylindrical shaped. strainer retained its position by using compression springs or strainer plugs. Fuel strainer is the usually removable type so that it can periodically take out and clean thoroughly. Now there are variety carburetor and choke cleaner solvents are available in market.Float chamber/ float mechanism

It is the main fuel supply chamber for the carburetor. Float chamber delivers the fuel to the nozzle at constant pressure head. Float chamber is designed to maintain a constant level of fuel in the chamber. The fuel level is slightly below the tip of fuel discharge nozzle to avoid overflowing of fuel when engine not running. The fuel supply valve to the float chamber is regulated by the float mechanism. Float valve mechanism includes float, the fuel supply valve and a pivot. When fuel flows into the chamber, the float rises. The movement of float actuates the fuel supply valve. At certain predetermined level of fuel, the float mechanism completely closes the fuel supply. When fuel flow to the venturi tube of the carburetor, the fuel level in the chamber decreases and the float also goes down. The downward movement of float leads the opening of fuel supply valve and then flow of fuel into the chamber.🔗Constant choke carburetor and constant vacuum carburetor

Main metering and idling system

Main metering and idling system control the fuel feed for cruising and full throttle operations. It consists of venturi, fuel metering orifice at the one end of fuel discharge nozzle, main discharge nozzle, and passes leading to the idling system. The functions of the fuel metering system are(i) Proportion the air-fuel mixture.

(ii) Decrease pressure at the discharge nozzle.

(iii) control the air flow at full throttle

During idling and at very low-speed running of the engine, the throttle is in closed or marginally opened position. So very small quantity of air passes through the nozzle during idling produce very little pressure depression across fuel discharge nozzle. This pressure depression is not enough to suck fuel from the float chamber. In order to provide rich mixture during idling, most modern carburetors incorporate an idling system. It consists of idling fuel passage and idling port as shown in the figure.

🔗Types of Air-Fuel mixture in carburation - Stoichiometric mixture, Rich mixture, and Lean mixture

In idling operation, the suction stroke decreases the pressure at the downstream side of the throttle, this pressure depression is enough to raise the fuel in the idling tube and discharge it through idling discharge port. A small amount of air is also sucked through idling air bleed, air mix with fuel (vaporize and atomize) as it passes through the idling passage. There will be some idling adjustment to regulate and keep the desired air-fuel ratio for idling. Bleed air also prevent the draining of fuel through idling tube due to siphon action.

Choke and throttle

When the vehicle keep stationary for long period, or starting of the engine in winter season may find some difficulty. At starting and very low-speed running engine require a rich air-fuel mixture for initiating and sustaining the combustion. Choke valves are used for this purpose. When choke valve manually pulled, it rotates an angle and restrict the air flow to the cylinder of IC engine and hence supply rich air-fuel mixture. Choke valve is usually a butterfly valve mounted in upstream of the carburetor. When choke partially closed it produces a higher partial vacuum inside the carburetor, which increases the amount of fuel flow from the main discharge nozzle. Opening of choke valve restores the normal operation of the carburetor. In modern design of carburetor the choke made works automatically by using thermostat and spring loading.Throttle is the main valve that controls the engine speed. This valve operated by accelerator vehicle by using mechanical linkage or by using the pneumatic method. It locates at downstream side to the venturi. Throttle regulate the quantity of charge flow into the cylinder. The more throttle valve opens the more air-fuel mixture flow into the engine cylinder it accordingly increase the output of the engine. When throttle is closed partially, it create more obstruction to charge flow in to the engine and reduces the engine output.