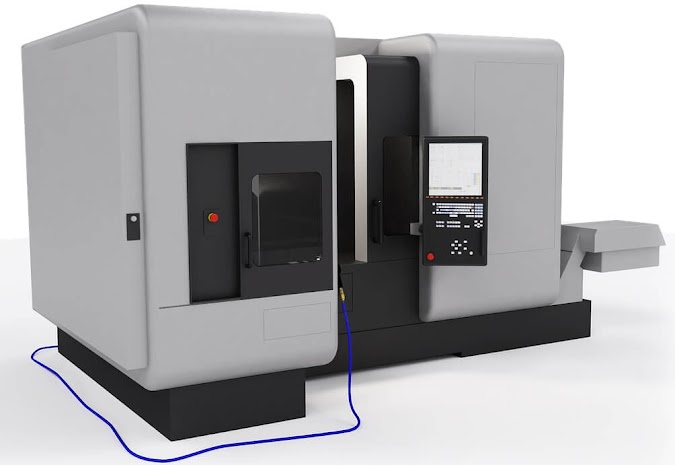

What is CNC (Computer Numerical Control)? Advantages, Limitations, Applications

CNC (Computer numerical control) System is similar to NC system, and it uses stored program to perform an operation instead of using Punched tapes. In old CNC machines the part program is initially entered similar to the conventional NC machine. Punched tape reader is the common device to input part program. In NC machine punched tape is needed to cycle through a reader for every workpiece, while in CNC the tape reader is used only once for the first loading of part program. Entered part program in first workpiece is stored in computer memory. It provides additional flexibility and computational capability over conventional NC machine. In latest CNC, the part program is created and then input it into machine by using CAD/CAM software.

Read : Comparison between CNC and DNC - Advantage and functions of DNC

Advantages of CNC

The CNC has many advantages over conventional NC. Some of the advantages are- The part program is needed to enter only once. The program tape and reader used once to enter part program to the computer memory. This reduces the use of unreliable tape reader (reduce data reading error).

- CNC can diagnose part program and find malfunctioning before part is produced.

- The program tape is editable - the NC tape can be corrected and optimize during try out at machine site.

- Flexibility – Greater flexibility provides the relatively easy opportunity to introduce new control option at low cost. This reduces the risk of obsolescence of the system.

- Metric conversion – CNC help to convert the tape prepared in unit of inch into SI unit

- Productivity increase, High accuracy and repeatability

- It facilitates the complex manufacturing operation.

- Reduce the indirect cost of manufacturing.

- CNC improves the production planning control.

- Total manufacturing system. It is compatible with the use of fully computerized factory wise manufacturing system. The CNC can integrated to DNC (Direct numerical control system) in highly sophisticated manufacturing system.

Disadvantages of CNC

- High installation cost and maintenance cost.

- Still need some skilled labour (computer knowledge). One of the sad side of CNC is that, suppressing of matamatical and design skill of an engineer.

- Special air-conditioned area is required for installation the CNC.

Common application of CNC

The CNC machines are used in following manufacturing processGrinding machine, Drilling machine, Tapering machine, Milling machine, Boring machine, Welding machine, Wire Cut EDM. CNC is applicable to all NC machine applications.

Read : What Are the Functions of Computer Numerical Control CNC?