Terms Used In Casting Process

Here are the typical terms used in sand casting

Bottom board: It is used at the starting of mold making. They are typically made of wood

Pattern: It is the replica of the final product with certain modification (allowance, provision of core print, etc.). The cavity of the mold is created with the help of a pattern. Patterns are slightly larger than the casting. They are made of wood, metal, plastic, etc.

Read: Types of Pattern Material - Application, Advanatages And Limitation

Molding sand: The refractory material that creates the mold cavity. It is a mixture of silica, clay, and moisture in appropriate proportion. It surrounds the pattern while making mold cavity.

Backing sand: It is the outermost layer of sands. It constitutes more volume in a mold. They are normally burnt sand.

Facing sand: Innermost and least volume layer of sand. They applied to the inner surface of the mold cavity to ensure the better surface finish of cast.

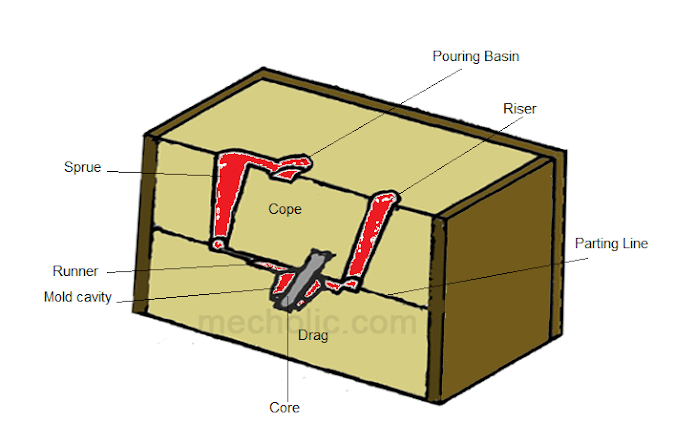

Flask: This is where the sand mold is held. Flask made of woods is used for temporary application, for long-term use the metal is used. Depending upon the position it is referred by various names such as Drag (lower molding flask), Cope (upper molding flask), Cheek (intermediate molding flask)

Parting line: This divides the two molding flask, the same line divides the two halves of the pattern in the split pattern.

Core and chaplet: Cores are used for making hollow cavities in casting. The chaplet is used to support cores inside the mold cavity.

Chill: These are the metallic object placed inside the mold cavity to ensure uniform (or desired) cooling rate of molten metal. They act as a heat sink and enable rapid localized cooling.

Pouring basin: It is a funnel-shaped structure at the top of the mold. Molten metal is poured into pouring basin.

Sprue: Molten metal flow from pouring basin to the mold cavity through a passage known as sprue. It controls the flow of molten metal.

Runner: These are the passageways in parting line that regulate the molten metal to the cavity.

Gate: The actual entry point of molten metal to the mold cavity.