What Is Tooling? (In Manufacturing)

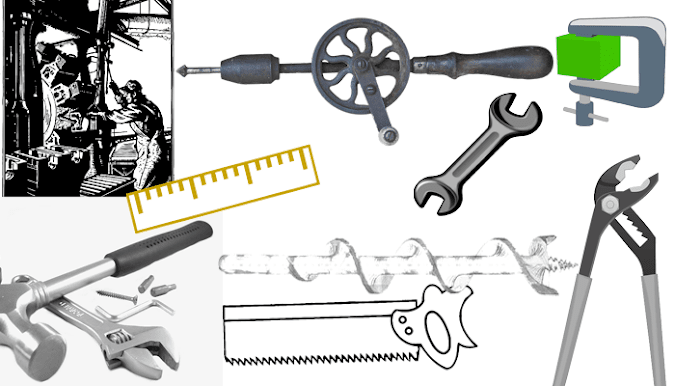

Tooling, also known as machine tooling, has referred to the process of providing industry or factory with necessary equipment and tools for a particular manufacturing process. Tooling includes cutting tools, jigs, fixtures, gauges, dies, molds, patterns, etc. The required equipment varies from one specific production to another. It depends on type, size and other process requirements. Having correct tooling is important to get work done in a right way and keep operations at their peak level. Without suitable tooling, the manufacturing process is rendered inefficient. Any change in tooling directly affects the production quantity, quality, life, and pricing.

Machine tools are used throughout the manufacturing process. The application of tools ranges from machining to inspection. They are used to cut, clamp, align, assemble, inspection, etc.

The common types of tooling are as follows

- Cutting tools – drills, broaches, milling

- Jig and fixtures for holding the workpiece and guide the tools.

- Gauges for measurements.

- Press tools

- Dies

Tool Engineer responsible for design and development of tools and integrating facilities for production with minimum material and expenditure. In order to minimize the cost of tooling, use standard tools whenever possible and utilize previously engineered design concepts.

Read: Factors affecting the design of tools