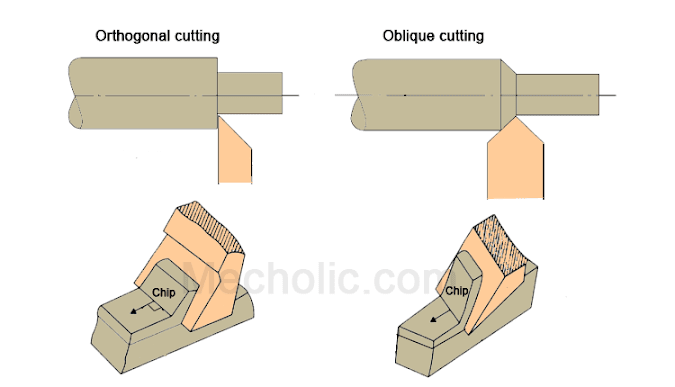

Difference between Orthogonal and Oblique Cutting

Read: Orthogonal cutting and oblique cutting

Comparison between the orthogonal and oblique cutting

Comparison between the orthogonal and oblique cutting

Orthogonal cutting

|

Oblique Cutting

|

The cutting edge of the

tool is perpendicular to the direction of feed motion.

|

The cutting edge of the

tool is inclined to the direction of feed motion.

|

The chip flow angle is

more than zero.

|

|

There are only two

components of force; these components are mutually perpendicular.

|

There are three mutually

perpendicular forces acting while cutting process.

|

The cutting edge is larger

than cutting width.

|

The cutting edge may or

may not be larger than cutting width.

|

Chips are in the form of a

spiral coil.

|

Chip flow is in a sideways

direction.

|

High heat concentration at

cutting region.

|

Less concentration of heat

at cutting region compared to orthogonal cutting.

|

For a given feed and depth

of cutting, the force acts on a small area as compared with oblique cutting,

so tool life is less.

|

Force is acting on a large

area, results in more tool life.

|

Surface finish is poor.

|

Good surface finish

obtained.

|

Used in grooving, parting,

slotting, pipe cutting.

|

Used almost all industrial

cutting, used in drilling, grinding, milling.

|